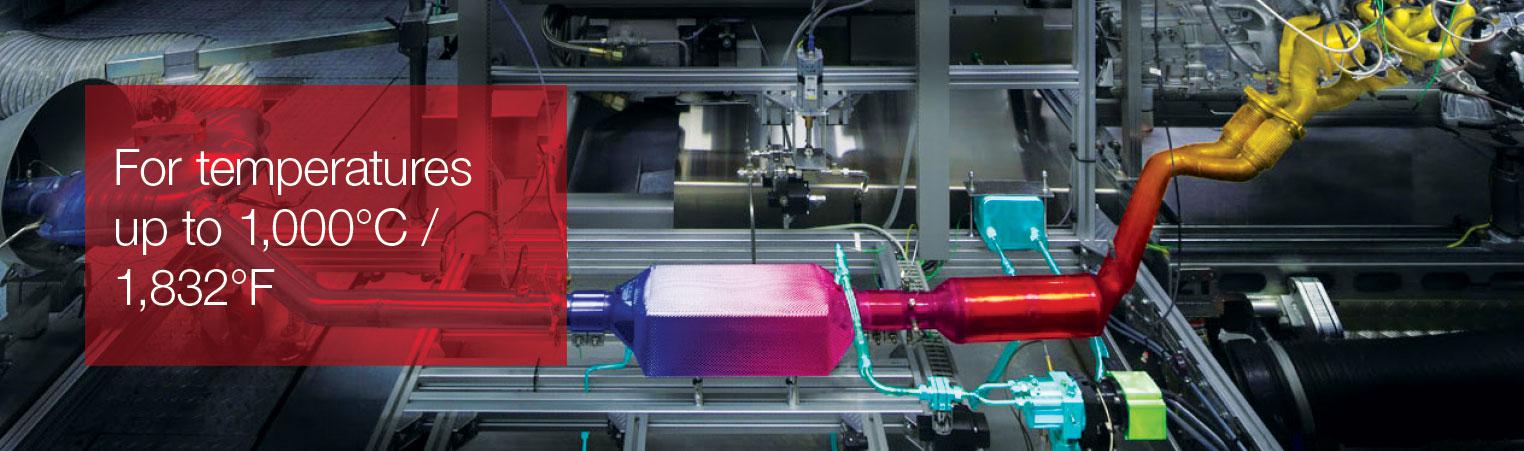

High temperature heat exchangers

For demanding high-temperature environments up to 1,000°C and outputs ranging from 250kWe up to 1MW or more, BOSAL ECI offers tailor-made, modular plate heat exchangers that recycle heat from exhausts. These highly efficient, compact energy conversion systems can be fully integrated into your power system.

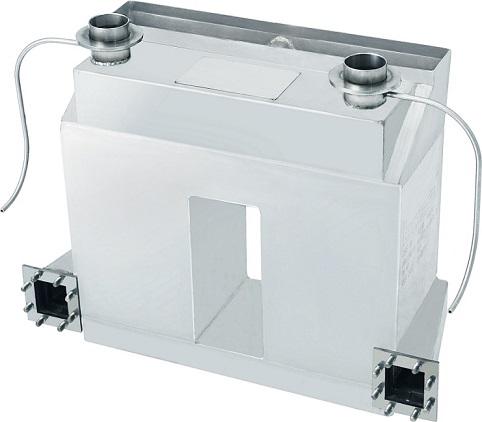

Plate heat exchangers

- High-temperature applications up to 1000°C

- Heat to power and power to heat

- Uniform flow with low back pressure

- Effectiveness up to 90%

- Interfacing tailored to your specifications

- > 40,000 field operating hours per module and counting

- Compact, modular architecture based on seven standard cell plate footprints

- Protective or catalytic coatings available

- High-quality stainless steel materials

System applications

- Combined Heat and Power (CHP) systems (residential and commercial)

- Prime power systems (residential and commercial)

A wide range of power plant applications

High-efficiency plates

ECI plate heat exchangers a deliver high contact surface density between two gas flows (more than 1.2 m2/liter) like one air flow and one exhaust flow. These highly efficient energy conversion systems deliver intensive heat transfer in combination with low pressure-drop and can be used in both co-flow and counter-flow configurations. Offering heat recovery at temperatures similar to the feeding heat flow, they can achieve efficiencies of up to 90% or more

Advanced modular components

With different plate sizes, BOSAL ECI offers the best modular footprint suited to your requirements. Whether it concerns a compact or large system, together with you we design, test, build and manufacture modules that are fully integrated into your energy power system according to your precise specifications.

Based on your system’s heat recovery needs, our compact, versatile modules can also be configured to function as:

- Pre-heaters to recycle waste heat (e.g. in Stirling engines)

- Reformers to convert hydrocarbons into hydrogen (e.g. in SOFC systems)